About Diffusion Furnace Refurbishment

Diffusion Furnace Refurbishment Capabilities

- Applicable Maker : TEL, KE (Kokusai Electrics), and etc.

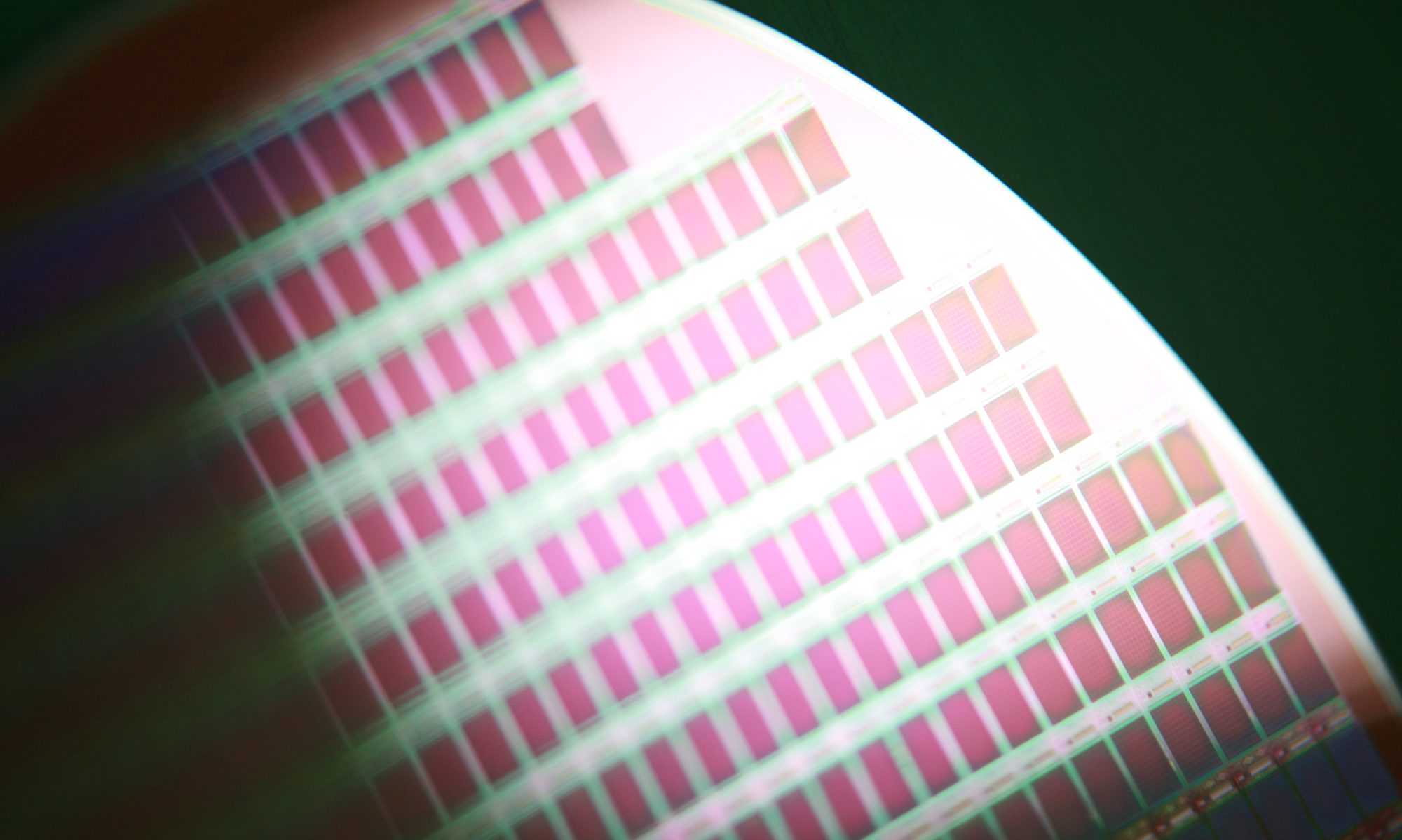

- Wafer Size : 200mm, 300mm

- Process Capabilities : HCD ALD Nitride, ALD Nitride, MTO, DCS-MTO, BCD-POLY, NS-POLY / LT-POLY, SEED-POLY, TEOS, and etc.

- Software Capabilities : I/O Mapping, PLC Program, S/W & H/W Interlock

- Hardware Capabilities : Main heater, Junction box module, Main power box, Jacket & Tape heater, Non loadloack to Loadloack modiication, Loadlock to Non loadlock modification, Wafer transfer module, Manifold & Seal cap module change, Auto shutter module change, PCW module, and etc.

- Parts Installation : PCB (MFC D-NET Board, etc..), Temperature Controller (RCM, CVM), Fork & Wafer detection module, Jacket & Tape heater, Valve block heater, and etc

Diffusion Furnace Refurbishment Work Flow

- On-Site Diffusion Furnace Refurbishment

- Off-Site Diffusion Furnace Refurbishment

Diffusion Furnace Relocation

Coming Soon !!!

TEL Formula Refurbishment

Coming Soon !!!

If you need more information, please leave your contact information. Contact Us