Thi Quynh Nguyen a,b,⇑, Hervé Fontaine a, Yannick Borde b, Véronique Jacob c

Abstract

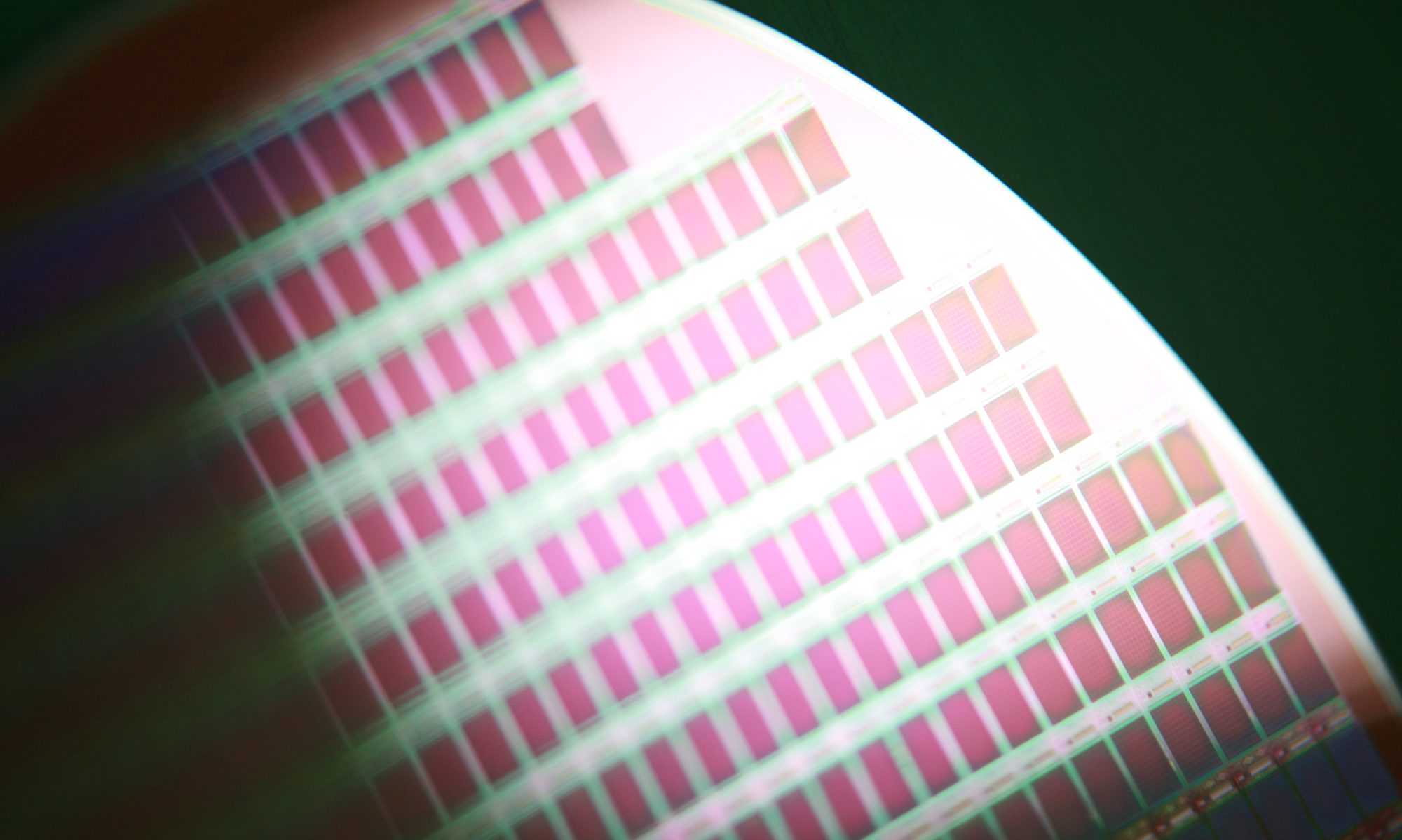

In the semiconductor industry, the control of contaminants is mandatory in order to prevent their detrimental impact on manufacturing yield. More specifically, it has been found that molecular contaminants coming from FOUPs could lead to defects on wafer. This paper presents two cases related with defects induced by molecular contamination, namely crystal growth and corrosion issues, respectively along two process sequences: (1) copper interconnect patterning and (2) Ionic Implantation of N-type or P-type

dopants before Spacer Deposition. Three main ionic contaminants have been identified: HF, CH3COOH, HCOOH with levels varying from few ppbv to few tens of ppbv. In the first process sequence, dry Etching step has been identified as the source of contamination. In the second process sequence CF4 dry Stripping step generates HF. On the other hand, dry Stripping step and Implantation step generate CH3COOH, HCOOH. Organic contaminants have been characterized showing that the FOUP atmosphere represents

a contaminated environment (about few tens of ppbv for total organics). A specific organic composition has been identified for in-process FOUPs but has not been related to a process or defects.